Greenhouse Gas Mitigation Solution

Products

01 PFCs Treatment Technology

Our catalytic PFCs decomposition system was developed with the world’s first large capacity. Non-metallic catalytic forming technology, which is suitable for large systems, is applied, and energy consumption is lower than direct heat incineration, and 95% heat recovery is possible.

02 Hybrid PFCs Decomposition System

Our catalytic PFCs decomposition system and plasma method are applied to this hybrid product. With the size of the product miniaturized, space utilization is increased. The product is more economical and efficient since only the advantages of the catalytic method and the plasma method have been combined is.

03 De-N2O & NOx Treatment Technology

The De-N2O & NOx System is equipment that breaks down N2 + H2O using catalysts such as N2O and NOx. With just one kind of catalyst, N2O and NOx can be removed at the same time. Located in the front or back end of a turbine, the system is operated at 400~500℃ and NH3 is used as a reducing agent.

Greenhouse Gas Mitigation Solution

(Catalyst specialized to secure conversion rate higher than 90% in both low and high temperature)

Independent development/production of greenhouse gas mitigation

11 years of know-how for the installation of greenhouse gas mitigation facility

Possess the reference of the installation of before/after turbine in domestic and overseas market

Based on these technologies, we're going to be able to...

Carbon credits business-

01 Obliged to mitigate global greenhouse gas along with Paris Agreement(Implemented from 2021)

-

02 Acknowledged by UNFCCC regarding the greenhouse gas mitigation performance by developing country's business

-

03 Invested on the developing country's business with the technology/resources to mitigate greenhouse gas

-

04 Sold the acknowledged greenhouse gas mitigation performance to CER market in Korea

(Global warming potential of N2O is 265)

6 Critical Greenhouse Gases

01 Carbon Dioxide[CO2]

CO2 is produced by deforestation, energy use, and the combustion of fossil fuels, such as coal and petroleum. The global warming potential (GWP) is 1, and it accounts for 88.6% of the total emission.

02 Methane[CH4]

Methane is usually produced by rearing livestock and from wetlands, rice paddies, food waste, etc. The GWP is 21, and it accounts for 4.8% of the total emission.

03 Nitrous Oxide[N2O]

Nitrous oxide is usually produced by the use of coal and chemical fertilizers, such as nitrogen fertilizer, and waste incineration. The GWP is 310, and it accounts for 2.8% of the total emission.

04 Hydrofluorocarbons[HFCs]

Hydrofluorocarbons are usually produced by air conditioner refrigerant and spray propellants. The GWP is is 140-11,700.

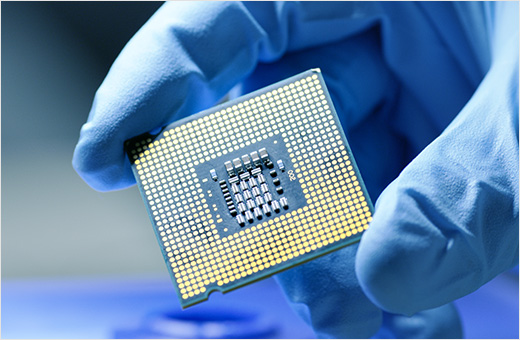

05 Perfluorocarbon[PFCs]

This gas is emitted from semiconductor cleaning agents, etc. The GWP is 6,500-9,200.

06 Sulphur Hexafluoride[SF6]

This is mainly produced by electric products, electric transformers, and insulators used in display manufacturing. The GWP is 23,900.

Chemical materials

Selectively remove harmful gases through physical and chemical adsorption and decomposition using a variety of adsorbents and catalysts.

From industrial facilities for air pollution prevention to clean filters such as households, vehicles, gas masks, etc.

ECOSORB IAC-130

ECOSORB IAC-130It adsorbs harmful gases from atmosphere, industrial site exhausts, laboratory hoods, etc. It controls various gases such as acid (SOx, NOx, HCl, HF, etc.), base (NH3, TMA), low-grade fatty acids, and ozone.

ECOSORB IAC-900

ECOSORB IAC-900It adsorbs various organic gases (VOCs) from the process of handling paint, the process of using glue, the semiconductor using organic solvents, the display process, and the laboratory experimenting with them. Typically, it controls various VOCs gas such as toluene, benzene, xylene, MEK, IPA, acetone, PGMEA, butylacetate, HMDS, and methylene chloride.

ECOSORB IAC-100

ECOSORB IAC-100It removes all kinds of odor-causing gases from public operating facilities and industrial sites such as food waste, water purification, sewage, and wastewater treatment plants. H2S, CH3SH, DMDS, Acetaldehyde, formaldehyde, and low-grade aldehyde control a variety of gases.

ECOSORB IAC-139

ECOSORB IAC-139It removes various complex odour gases from public operating facilities and industrial sites such as biogasification, food, sewage, and wastewater treatment plants. Controls 22 types of odour containing acid, base, aldehyde, sulfur compound gas, and volatile organic compound gas.

ECOSORB IAC-1390

ECOSORB IAC-1390Absorb and remove various acidic and toxic gases from semiconductor fair and waste gases.arsine(AsH3), phosphine(PH3), CO, Cl2, F2, SiF4, GeF4, SiH4, BCl3, H2SO4, HCl, BBr3 Controls various gases.

PFC Decomposition Catalyst(NOx+N2O)

PFC Decomposition Catalyst(NOx+N2O)Although it was necessary to decompose the PFCs gas emitted during the semiconductor manufacturing process, our catalyst is a specialized product that shows 99% removal efficiency at temperatures below 750℃ using PFC catalyst that leads to low-temperature oxidation.

VOCs Oxidation Catalyst

VOCs Oxidation CatalystTHCs in various industries such as paint, adhesion, and coating processes vary greatly from concentration, gas composition, gas volume, temperature to temperature, and our VOCs oxidation catalyst has developed a catalyst that can oxidize VOCs from low to high temperature to efficiently eliminate THCs.

CO+VOCs+O3 Catalyst

CO+VOCs+O3 CatalystEcopro's chemical catalyst is a product that selectively decomposes various harmful gases from industries, homes, and public facilities into harmless gases through catalytic oxidation reactions. It adsorbs industrial sites and semiconductor fair value and carbon monoxide (CO) generated in daily life at room temperature and removes them through catalytic oxidation reactions.

Composite Odor Catalyst

Composite Odor CatalystEcopro's composite odor catalyst is a chemical catalyst that can decompose complex odor gases such as high concentrations of sulfur compounds, aldehydes, low-grade fatty acids, and ammonia at low and medium temperatures (80-400℃) in public treatment facilities such as food waste, sewage, wastewater and manure treatment plants. This is a Hybrid system that eliminates odour gases by linking chemical adsorbents and catalysts.

SCR Catalyst

SCR CatalystNitrogen oxides are typically caused by the combustion of fuels such as LNG, heavy oil and diesel, coal, etc. from fixed sources of heat-merged power plants, incinerators, industrial boilers, or automobiles, ship engines, locomotives. Ecopro's catalyst is a specialized catalyst that can achieve a high conversion rate of more than 90% at low and high temperatures.