Clean Room Chemical filter

AMCs?

AMC(Airborne molecular contamination) refers to various chemical pollutants (organic, base, acidic gas, etc.) that negatively affect semiconductor plants.

Applicable field

- Ultra-precise manufacturing process such as semiconductor and LCD

- On the site of the odor and harmful gas generation industry

- In areas requiring clean environment such as hospitals, museums, and public institutions

Features

- 90% higher removal efficiency and longer lifetime

- Create customized filters at customer request

- Easy to operate installation

- Excellent price competitiveness

- Batch deployment of line-up from attached media to finished assembly and installation

Examples of filter applications

product descriptions

01 CAFILDEX® SW series

It's a panel-type product with multiple layers of media, and SW is a product name derived from SandWich. SW Media consists of multiple layers for complex gas control. Frame material and removal gas can be customized by considering the customer's request and site, so the customer's satisfaction is high.

02 CAFILDEX® HECY series

When installing a cylindrical product, it can be installed immediately without a buffer frame, and the composite gas control can be done the same as SW series by applying SW Media. Frame material uses aluminum anodized material and is mainly applied for FFU.

03 CAFILDEX® TY series

Multi-Tray Type has the advantage of low pressure loss by expanding the area, and Tray can control various gases depending on the mixing method by filling the media in the form of a pellet. In addition, BOX is semi-permanent with SUS material, and it reduces operational maintenance costs by replacing the Tray.

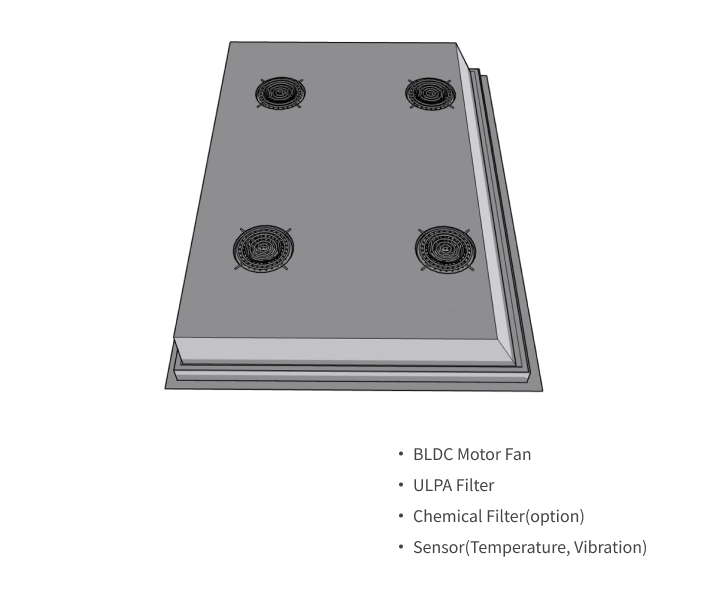

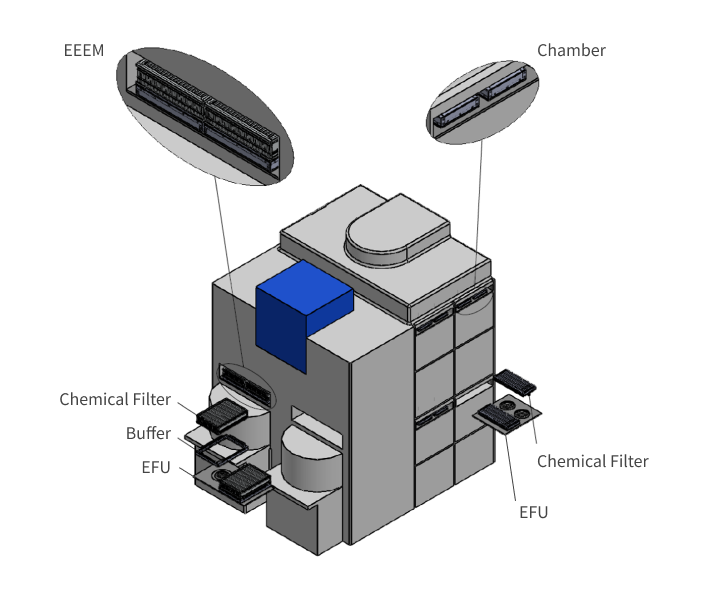

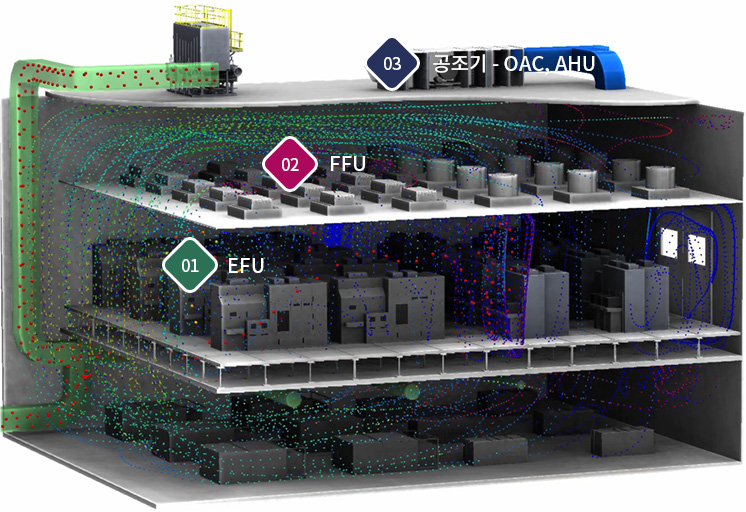

EFU(Equipment Fan filter Unit)

Maintain an optimal process environment by removing particles

and gases within semiconductor and display facilities.

Through customized designs such as EFEM and equipment chambers, we supply optimal air

at a uniform flow rate in a restricted environment to suppress defects.

Technical introduction

- EFU(Fan)

- ULPA

- Chemical

Filter

Example

Chemical materials

Selectively remove harmful gases through physical and chemical adsorption

and decomposition using a variety of adsorbents and catalysts.

From industrial facilities for air pollution prevention to clean filters such as households, vehicles, gas masks, etc.

ECOSORB IAC-130

ECOSORB IAC-130It adsorbs harmful gases from atmosphere, industrial site exhausts, laboratory hoods, etc. It controls various gases such as acid (SOx, NOx, HCl, HF, etc.), base (NH3, TMA), low-grade fatty acids, and ozone.

ECOSORB IAC-900

ECOSORB IAC-900It adsorbs various organic gases (VOCs) from the process of handling paint, the process of using glue, the semiconductor using organic solvents, the display process, and the laboratory experimenting with them. Typically, it controls various VOCs gas such as toluene, benzene, xylene, MEK, IPA, acetone, PGMEA, butylacetate, HMDS, and methylene chloride.

ECOSORB IAC-100

ECOSORB IAC-100It removes all kinds of odor-causing gases from public operating facilities and industrial sites such as food waste, water purification, sewage, and wastewater treatment plants. H2S, CH3SH, DMDS, Acetaldehyde, formaldehyde, and low-grade aldehyde control a variety of gases.

ECOSORB IAC-139

ECOSORB IAC-139It removes various complex odour gases from public operating facilities and industrial sites such as biogasification, food, sewage, and wastewater treatment plants. Controls 22 types of odour containing acid, base, aldehyde, sulfur compound gas, and volatile organic compound gas.

ECOSORB IAC-1390

ECOSORB IAC-1390Absorb and remove various acidic and toxic gases from semiconductor fair and waste gases.arsine(AsH3), phosphine(PH3), CO, Cl2, F2, SiF4, GeF4, SiH4, BCl3, H2SO4, HCl, BBr3 Controls various gases.

PFC Decomposition Catalyst(NOx+N2O)

PFC Decomposition Catalyst(NOx+N2O)Although it was necessary to decompose the PFCs gas emitted during the semiconductor manufacturing process, our catalyst is a specialized product that shows 99% removal efficiency at temperatures below 750℃ using PFC catalyst that leads to low-temperature oxidation.

VOCs Oxidation Catalyst

VOCs Oxidation CatalystTHCs in various industries such as paint, adhesion, and coating processes vary greatly from concentration, gas composition, gas volume, temperature to temperature, and our VOCs oxidation catalyst has developed a catalyst that can oxidize VOCs from low to high temperature to efficiently eliminate THCs.

CO+VOCs+O3 Catalyst

CO+VOCs+O3 CatalystEcopro's chemical catalyst is a product that selectively decomposes various harmful gases from industries, homes, and public facilities into harmless gases through catalytic oxidation reactions. It adsorbs industrial sites and semiconductor fair value and carbon monoxide (CO) generated in daily life at room temperature and removes them through catalytic oxidation reactions.

Composite Odor Catalyst

Composite Odor CatalystEcopro's composite odor catalyst is a chemical catalyst that can decompose complex odor gases such as high concentrations of sulfur compounds, aldehydes, low-grade fatty acids, and ammonia at low and medium temperatures (80-400℃) in public treatment facilities such as food waste, sewage, wastewater and manure treatment plants. This is a Hybrid system that eliminates odour gases by linking chemical adsorbents and catalysts.

SCR Catalyst

SCR CatalystNitrogen oxides are typically caused by the combustion of fuels such as LNG, heavy oil and diesel, coal, etc. from fixed sources of heat-merged power plants, incinerators, industrial boilers, or automobiles, ship engines, locomotives. Ecopro's catalyst is a specialized catalyst that can achieve a high conversion rate of more than 90% at low and high temperatures.