Research Direction

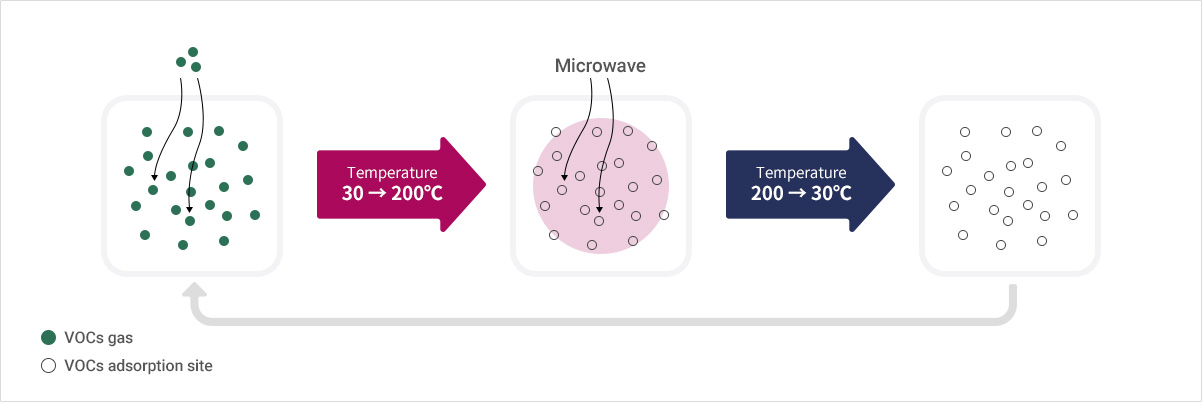

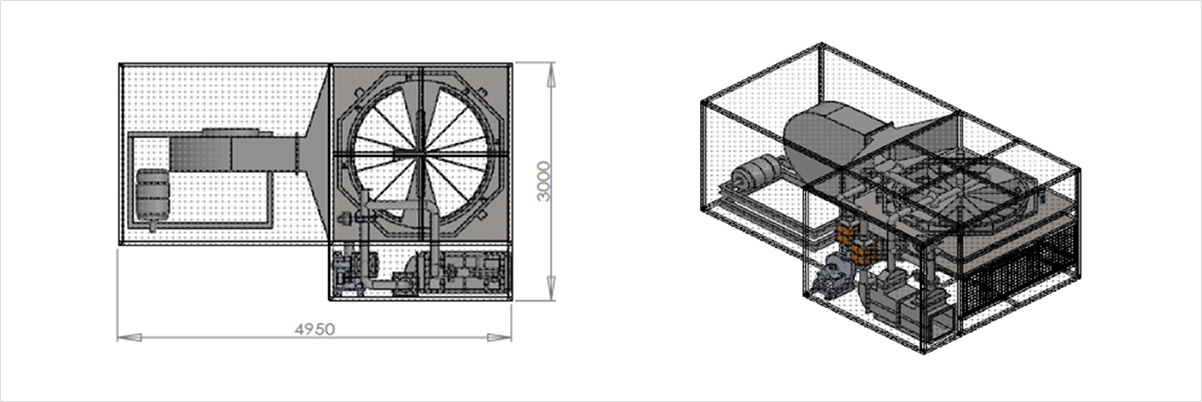

EcoProHN developed and commercialized a Volatile Organic Compounds (VOCs) reduction system using MW. By using both hot air and MW as heat sources for VOCs regeneration and catalytic reaction, energy efficiency has been improved by 30% compared to existing facilities that only use hot air. We have developed a dedicated adsorbent that can absorb MW energy at the same time as VOCs adsorption, and we are developing it to achieve the best performance.

Major Research Areas

- Development of VOCs Adsorbent

- Development of VOCs Catalyst

- A Study on the Improvement of VOCs Reduction System and Microwave Efficiency