Fine dust reduction solutions

Fine dust reduction solutions

It is a system that removes or reduces air pollutants emitted from industrial sites and substances harmful to the human body,

such as VOCs, NOx, SOx, and combined odors.

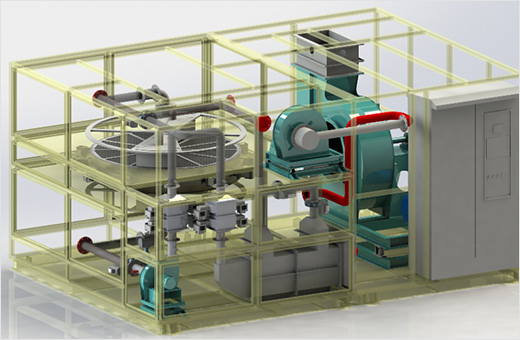

Combustion System

01 Thermal Storage Combustion Facility(RTO)

It is a high-efficiency energy-saving facility that processes VOCs and odor gases emitted by the process by combustion (oxidation) at high temperatures and recovers heat generated by combustion using heat accumulation materials. It is mainly applied to VOCs and organic odor generating facilities such as printing plants, petrochemicals, semiconductors, adhesive tapes, drugs, painting, food processing, wastewater treatment, and wires.

02 Catalyst Combustion Facility(RCO, CTO)

It is a system that can reduce the energy required for VOCs combustion (oxidation) using catalysts, and is economical using only about 30% to 40% of the energy than direct combustion. It is mainly applied to VOCs and organic odor generating facilities such as printing plants, petrochemicals, semiconductors, adhesive tapes, drugs, painting, food processing, wastewater treatment, and wires.

Enrichment system

01 Concentrator + Combustion Facility(CRTO)

It is a system that adsorbs medium and low concentrations of VOCs with zeolite and desorbs them with high-temperature gas for picnics and processes high-concentration gases with combustion facilities. It is mainly applied to printing, painting, coating, cleaning, refinery process, etc.

MW System

01 Microwave VOCs Removal Facility

After adsorption of VOCs using adsorbent, Microwave is investigated and desorbed, VOCs are a system that concentrates up to 1/40 small wind volumes and catalyzes them. Energy savings of more than 30% are possible compared to existing facilities when dealing with low concentration of low concentration. It is mainly applied to printing, painting, coating, cleaning, refinery process, etc.

De-NOx System

01 SCR

It is a system that effectively processes the reduction reaction of NOx at a relatively low temperature of 250~400℃ by spraying reducing agents (ammonia, etc.) into the stomach gas and passing through the catalyst layer. Mainly boilers, power generation facilities, wastewater, waste.It applies to waste gas incineration facilities, etc.

02 SNCR

It is a system that dispenses reducing agents (ammonia, etc.) into the ship gas and passes through the combustion chamber without a catalyst and processes them through a reduction reaction of NOx at 850~1100℃. Mainly boilers, power generation facilities, wastewater.It applies to waste, waste gas incineration facilities, etc.

Composite Odor and VOCs Removal System

01 MDS

It is a system that can be installed for local exhaust at sites where emergency hazardous gas leaks and process pollutants occur. It is simple to operate, can handle more than 95% of harmful gases in a short time, and is mainly applied to indoor hazardous substances such as laboratories and factories.

02 Adsorption facility

It is a facility that removes VOCs by physical adsorption at below 50℃ using a porous adsorbent such as activated carbon. In addition, selective chemical adsorbents can be designed to reduce hydrogen sulfide and complex odor gases such as ammonia and aldehyde gas by less than 500 times the odor drain. It is mainly applied to painting, painting, adhesion, painting process, food waste disposal, livestock manure, sewage, wastewater treatment plants, and biogasification facilities.

03 Absorption facility

It is a system that processes odorous gases by making contact with the absorption liquid, so that odorous gases dissolve well in liquid, or use chemically reactive properties to deal with odorous gases. It is mainly applied to facilities that produce odorous substances such as chemical fertilizer manufacturing facilities and plastic facilities.

Total Service

Chemical materials

Selectively remove harmful gases through physical and chemical adsorption and decomposition using a variety of adsorbents and catalysts.

From industrial facilities for air pollution prevention to clean filters such as households, vehicles, gas masks, etc.

ECOSORB IAC-130

ECOSORB IAC-130It adsorbs harmful gases from atmosphere, industrial site exhausts, laboratory hoods, etc. It controls various gases such as acid (SOx, NOx, HCl, HF, etc.), base (NH3, TMA), low-grade fatty acids, and ozone.

ECOSORB IAC-900

ECOSORB IAC-900It adsorbs various organic gases (VOCs) from the process of handling paint, the process of using glue, the semiconductor using organic solvents, the display process, and the laboratory experimenting with them. Typically, it controls various VOCs gas such as toluene, benzene, xylene, MEK, IPA, acetone, PGMEA, butylacetate, HMDS, and methylene chloride.

ECOSORB IAC-100

ECOSORB IAC-100It removes all kinds of odor-causing gases from public operating facilities and industrial sites such as food waste, water purification, sewage, and wastewater treatment plants. H2S, CH3SH, DMDS, Acetaldehyde, formaldehyde, and low-grade aldehyde control a variety of gases.

ECOSORB IAC-139

ECOSORB IAC-139It removes various complex odour gases from public operating facilities and industrial sites such as biogasification, food, sewage, and wastewater treatment plants. Controls 22 types of odour containing acid, base, aldehyde, sulfur compound gas, and volatile organic compound gas.

ECOSORB IAC-1390

ECOSORB IAC-1390Absorb and remove various acidic and toxic gases from semiconductor fair and waste gases.arsine(AsH3), phosphine(PH3), CO, Cl2, F2, SiF4, GeF4, SiH4, BCl3, H2SO4, HCl, BBr3 Controls various gases.

PFC Decomposition Catalyst(NOx+N2O)

PFC Decomposition Catalyst(NOx+N2O)Although it was necessary to decompose the PFCs gas emitted during the semiconductor manufacturing process, our catalyst is a specialized product that shows 99% removal efficiency at temperatures below 750℃ using PFC catalyst that leads to low-temperature oxidation.

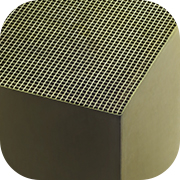

VOCs Oxidation Catalyst

VOCs Oxidation CatalystTHCs in various industries such as paint, adhesion, and coating processes vary greatly from concentration, gas composition, gas volume, temperature to temperature, and our VOCs oxidation catalyst has developed a catalyst that can oxidize VOCs from low to high temperature to efficiently eliminate THCs.

CO+VOCs+O3 Catalyst

CO+VOCs+O3 CatalystEcopro's chemical catalyst is a product that selectively decomposes various harmful gases from industries, homes, and public facilities into harmless gases through catalytic oxidation reactions. It adsorbs industrial sites and semiconductor fair value and carbon monoxide (CO) generated in daily life at room temperature and removes them through catalytic oxidation reactions.

Composite Odor Catalyst

Composite Odor CatalystEcopro's composite odor catalyst is a chemical catalyst that can decompose complex odor gases such as high concentrations of sulfur compounds, aldehydes, low-grade fatty acids, and ammonia at low and medium temperatures (80-400℃) in public treatment facilities such as food waste, sewage, wastewater and manure treatment plants. This is a Hybrid system that eliminates odour gases by linking chemical adsorbents and catalysts.

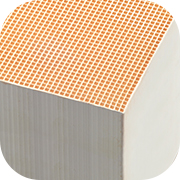

SCR Catalyst

SCR CatalystNitrogen oxides are typically caused by the combustion of fuels such as LNG, heavy oil and diesel, coal, etc. from fixed sources of heat-merged power plants, incinerators, industrial boilers, or automobiles, ship engines, locomotives. Ecopro's catalyst is a specialized catalyst that can achieve a high conversion rate of more than 90% at low and high temperatures.